INFRASTRUCTURE

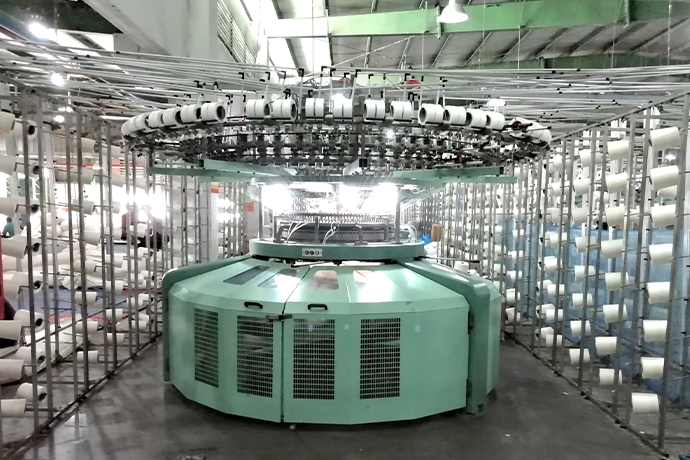

knitting

Knitting is one of the most ancient methods of fabric creation, used to produce a wide array of fabrics, from basic single jersey to complex and intricate designs. We specialize in creating custom knitted fabrics such as Nylon, Polyester, Acrylic, Wool, Viscose, Cotton, Lycra, Bamboo, and more. Our advanced knitting machines can produce a diverse range of fabrics, including jersey, pique, fleece, and specialized patterns like lace, intarsia, and jacquard. Additionally, we offer premium knitting, dyeing, finishing, and other services to meet a variety of client needs.

dyeing

Dyeing in garments refers to the process of applying color to fabric or clothing. It can be done using various techniques such as immersion dyeing, spray dyeing, or tie-dyeing. Different types of dyes, including natural and synthetic, are used depending on the fabric type and desired effect. Dyeing enhances the aesthetic appeal of garments, making them more vibrant or unique, while also allowing for custom colors and designs in fashion.

cutting

stitching

Stitching in garment manufacturing is the process of joining fabric pieces together to create the final product. Using industrial sewing machines, skilled operators sew the cut fabric parts, ensuring accuracy, strength, and durability in the seams. Stitching techniques vary depending on the garment type, fabric, and design, with different stitches used for different purposes, such as hemming, attaching trims, or reinforcing areas. Proper stitching is key to ensuring fit, comfort, and overall garment quality.

checking

Checking in garment manufacturing is a critical quality control step where finished products are inspected for defects, accuracy, and overall quality. This process includes checking for issues like stitching errors, fabric imperfections, incorrect sizing, or color discrepancies. Garments are also reviewed for proper finishing and trims. A final check ensures that each piece meets the required standards before packaging and shipment, ensuring customer satisfaction and maintaining brand reputation.

ironing

Ironing in garment manufacturing is the process of using heat and pressure to remove wrinkles, smooth fabric, and enhance the garment’s appearance. This step is essential to achieve a crisp, finished look before the garment is packed and shipped. Ironing also helps set certain fabric finishes, ensuring they maintain their shape. In high-volume production, industrial steam irons or pressing machines are used for efficiency, ensuring consistency and a polished final product.

packing

Packing in garment manufacturing involves preparing finished products for shipment to customers. This includes carefully folding, tagging, and placing garments into appropriate packaging, such as flat packs, hangers, or boxes, depending on the customer’s requirements. The packing process ensures that the garments are protected from damage during transit, are easy to handle, and maintain their quality. Proper packing also helps streamline inventory management and enhances the overall customer experience.

AR Creations © Copyright 2024. All Rights Reserved. designed by Iorange Innovation